Precision matters: Navigating the landscape of quality control in biologics

By the bioMérieux Editors | Reading time: 4 min

PUBLICATION DATE: MARCH 27, 2024

Humans have been using plant and animal derived products (biologics) to treat disease for thousands of years, but the advent of mass production in the 20th century enabled the growth of biologics as a recognized class of medicines. Unlike chemically derived medicines, which combine specific ingredients in an ordered process, biologics are typically very large, complex molecules or mixtures of molecules that are difficult to characterize.

In recent years, biologics have delivered new treatment approaches and transformed outcomes across a range of therapeutic areas. Key examples of biologics include:

- Vaccines, which are used to induce an immune response that delivers protection against infection or disease.

- Therapeutic proteins, which are genetically engineered versions of proteins that naturally occur in the body, such as insulin. They can be used to replace a protein that is abnormal or deficient and can bolster the body's supply of a protein to help reduce the impact of disease or treatment.

- Monoclonal antibodies, a type of therapeutic protein designed to serve as substitute antibodies that can restore, enhance, modify or mimic the immune system's attack on cells that aren't wanted, such as cancer cells.

- Growth factors, which stimulate cellular processes that can aid tissue repair and regeneration.

- Immune modulators, which work by either stimulating or suppressing the immune system and can help the body fight cancer, infection or other diseases.

- Other products derived from human blood and plasma offer a range of functions and are prescribed for many different diseases, such as coagulation factors, immunoglobins, albumin and protease inhibitors.

Safeguarding quality in the production of biological products

Quality control is a critical field of work within the pharmaceutical industry, helping to ensure the efficacy of therapeutics, as well as supporting their consistency across batches and ultimately maintaining safety for patients. When it comes to biologic therapeutics, their very nature requires an uncompromising approach to monitoring and quality control. The production of biologics harnesses intricate living systems which can be highly responsive to even the most subtle changes in their manufacturing process and environment. Minor deviations can notably alter the characteristics of the final biologic and impact how it works once administered to the patient.

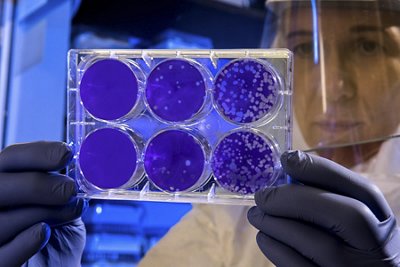

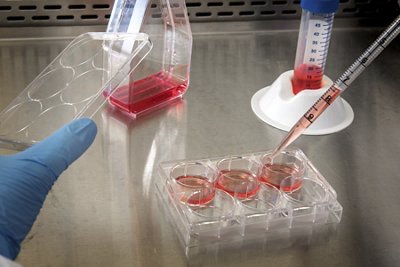

Another key consideration is maintaining sterility as many biologic therapeutics are administered directly into the bloodstream. Contamination can become present in multiple ways, from the initial raw materials used (e.g. cells, supplements), the surfaces of equipment, human individuals carrying out manufacturing processes and the transfer of materials into or out of an aseptic production process. Additionally, the use of sensitive raw materials like cell cultures makes biologics more susceptible to contaminants than other products.

Comparing cell-based vaccines and mRNA-based vaccines can help illustrate this principle: The production of cell-based vaccines relies on biological processes, requiring additional quality control tests to rapidly detect bacteria which could infect cells in the vaccine, such as mycoplasma. On the other hand, mRNA-based vaccines are created through synthetic processes, so whilst they can be contaminated in other ways, issues like mycoplasma contamination are not a concern as there are no cells to infect.

Partly due to their unique nature, the expansion of biologics as a therapeutic class has forced regulatory bodies to evolve and adapt their approaches to how they are categorized and regulated. In 1992, the World Health Organization (WHO) first issued its good manufacturing practices for biological products. Since then, WHO has drawn upon its accumulated collective experience with biologics to evolve a set of global regulatory standards, which set out minimum requirements for the approval of all biologic medicines.(1)

Additionally, the European Medicines Agency has produced extensive scientific guidelines regarding biologic medicines to support the submission of new marketing authorization applications for biologic therapeutics.(2) The US Food and Drug Administration has also recognized the growing importance of biologic medicines and initiated an abbreviated approval pathway for biologic products in response.(3)

A risk-based approach to designing quality systems for biologics

While industry regulations provide overarching manufacturing requirements that companies must adhere to, individual biologic products are all produced in different ways, requiring a risk-based approach to quality control at every part of the value chain. Testing and monitoring are at the heart of successful quality control; ensuring products remain within the required specifications at each stage of production, enabling manufacturers to determine any need for corrective action and ensuring the output is safe, effective and of acceptable quality when it reaches the market.

Whereas the manufacture of a chemically derived medicine may include 40-50 critical tests, for a biologic product this can run to 250 or more tests. (4) In the upstream phase (cell cultivation, fermentation), employing robust analytical techniques for raw materials screening ensures high-quality starting materials. Continuous monitoring of critical parameters such as cell growth, nutrient levels and metabolites allows for prompt adjustments, optimizing conditions for cell cultures. Additionally, implementing in-process testing, like biomarker assays, enables early detection of deviations, ensuring product consistency.

For the downstream phase (purifying and refining the harvested biologic material), high resolution techniques like chromatography and mass spectrometry can enhance the accuracy of purification processes, ensuring the removal of impurities and achieving high product purity. Robust testing for product quality attributes such as potency and stability helps confirm the biologic’s efficacy and shelf life. Additionally, employing real-time analytics allows for immediate adjustments, optimizing the efficiency of downstream operations.

Further testing considerations and variations in approach are also required depending on the type of biologic being produced.

Evolving approaches to quality control and assurance for a changing world

Trends show that the global biologics market is set to continue its rapid expansion over the coming years, with analysts predicting it will increase in value from $367.17 billion in 2023 to over $620 billion by 2032.(5) A key challenge of this growth is maintaining the balance between supply and demand, leading companies to invest in expanding their manufacturing capacity. The introduction of expedited review and approval pathways for novel biologics is also placing further pressure on manufacturers to cut the time it takes to bring their products to market.

One facet of emerging technology that could help enhance capacity and expedite production is advanced software that utilizes artificial intelligence (AI). By generating and analyzing data, AI can help manufacturers study their processes and create more sustainable and efficient systems, as well as predicting supply with higher accuracy. By building an effective feedback loop, manufacturers can apply learnings at every stage of the value chain to focus on the areas of greatest impact to product quality and yield.

The challenge to increase the supply of biologics is further compounded by an ongoing labor shortage in the sector, as manufacturers struggle to fill roles and retain experienced staff. While there can be no quick fix to overcome this issue, automation is increasingly viewed as a potential solution to overcome immediate bottlenecks, reduce reliance on expert staff and potentially alleviate capacity constraints. Integrating automation within biologic manufacturing could also offer the added bonus of reducing human error, eliminating opportunities for contamination and removing exposure to hazardous materials.

The growth of biologics as a vital area of modern medicine is undeniable, however maintenance of trust in these therapeutics is reliant on the combined vigilance of regulatory authorities and manufacturers, along with the ongoing innovation of more powerful and consistent tools to support quality control checks in an evolving landscape. Through this collaborative spirit, we can continue to harness the power of biologics to deliver transformative treatment options for prescribers and improve outcomes for their patients.

[1] International Alliance of Patient Organizations. Fact Sheet 2: Regulation of Biologics. Available at: https://www.iapo.org.uk/sites/default/files/files/factsheet2.pdf Last accessed February 2024.

[2] European Medicines Agency. Biological guidelines webpage. Available at: https://www.ema.europa.eu/en/human-regulatory-overview/research-and-development/scientific-guidelines/biological-guidelines Last accessed February 2024.

[3] U.S. Food and Drug Administration. Biosimilars: Review and approval webpage. Available at: https://www.fda.gov/drugs/biosimilars/review-and-approval Last accessed February 2024.

[4] Morrow T, Felcone LH. Defining the difference: What Makes Biologics Unique. Biotechnol Healthc. 2004 Sep;1(4):24-9.

[5] Precedence Research. Biologics Market (By Source: Microbial, Mammalian, Others; By Product: MABs, Vaccines, Antisense, RNAi & Molecular Therapy, Recombinant Proteins, Others; By Indication: Oncology, Immunological Disorders, Cardiovascular Disorders, Hematological Disorders, Others; By Manufacturing: Outsourced, In-house; By Distribution Channel) - Global Industry Analysis, Size, Share, Growth, Trends, Regional Outlook, and Forecast 2023 – 2032. Available at: https://www.precedenceresearch.com/biologics-market Last accessed February 2024.

You may be interested in these articles

SHARE THIS ARTICLE:

- Pharmaceutical Quality Control